Stellite Balls or cobalt alloy balls, have toughness, corrosion and abrasive resistance in high temperatures, stellite balls are used in check valves in petroleum industry and related fields.

Tantalum Balls Tantalum is a rare metal, highly corrosion-resistant, the chemical inertness of tantalum makes it a valuable substance for laboratory equipment, and as a substitute for platinum. Tantalum balls are widely used in medical and industrial applications

Titanium Balls 6AL4V ELI balls are the strongest of all the titanium alloys thanks to its higher aluminum and vanadium content. Titanium balls offer a versatile mix of good corrosion resistance, weldability, and formability. Titanium balls are widely used in medical and industrial applications.

Monel Balls K-Monel balls offer excellent corrosion resistance to mineral and organic acids, alkalies, salts, including chlorides. Further K-Monel balls offer the advantage of being non magnetic to minus 150°F.

Inconel Balls are available in various nickel base types. Inconel balls offer resistance to chemical corrosion and oxidation, retention of properties at elevated temperatures. Inconel balls are used in check valves in harsh environments, oil & gas and chemical processing and pollution control applications. Inconel balls are also used in the stud welding as fasteners in aerospace industry.

Aluminum Balls are widely used as bearings and in valves, aluminum balls are durable and lightweight. 2017-T4 Aluminum balls are used in automotive and aircraft applications, where durability, hardness & weight are factors. 1100 H16 Aluminum balls are primarily used in the Stud Welding Industry as fasteners.

Copper Balls with 99.99% purity maintain extreme softness, 102 copper balls have higher purity than 110 copper balls, resulting in superior electrical conductivity. It’s commonly called OFE and OFHC copper. Copper balls are used in electrical applications

Hastelloy Balls are available in various nickel molybdenum chromium alloy base types. Hastelloy balls offer excellent resistance to chemical corrosion and oxidation, retention of properties at elevated temperatures. Hastelloy balls are used in oil & gas and chemical processing, pollution control applications and check valves in harsh environments. Hastelloy balls are also used in the stud welding as welding filler in aerospace industry.

Titanium Carbide Balls, Tic balls, are extremely hard (Mohs 9–9.5) refractory ceramic material, similar to tungsten carbide. The resistance to wear, corrosion, and oxidation of a tungsten carbide material can be increased by adding 6–30% of titanium carbide to tungsten carbide

AISI S-2 „Rock Bit“ Tool Steel Balls S-2 Rock Bit Tool steel balls are suited to extreme conditions common to oil drilling, the material provide toughness, strength, shock and abrasion resistance. S-2 Rock Bit Toll steel balls have uniform hardness of 54 to 60 HRc.

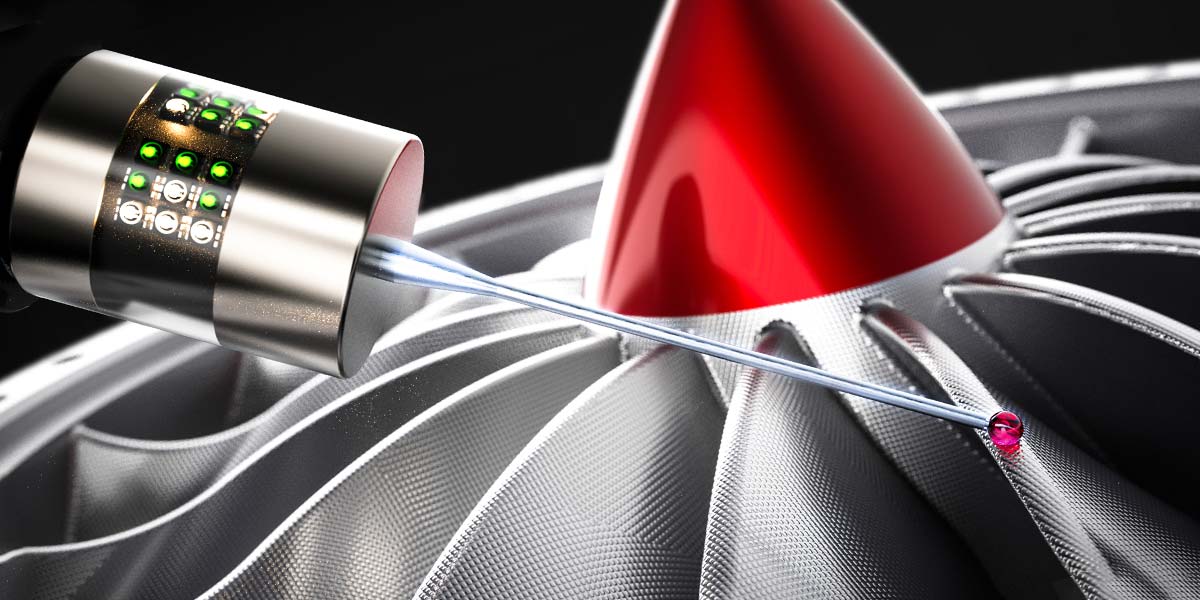

M50 High Speed Steel Balls are widely used for bearing applications in aerospace turbine engines operating at high temperatures. M50 high speed steel balls maintain the high wear resistance, thermal stability, oxidation resistance and compressive strength characteristics of high speed tool steel. M50 high speed steel alloy is produced by a vacuum arc remelt process (VIM VAR) to yield a super clean material. M50 high speed steel balls maintain a typical hardness range between 60 to 65 HRc.